At a glance

Alborz Petrochemical Industrial Service

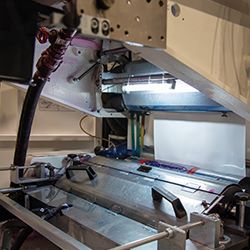

Alborz Petrochemical Industry Services Company, provides services to the

petrochemical industries using new technologies. The phase one of the company produces

three-layer films for packaging petrochemical products.

In the next phase, the production of other petrochemical downstream materials is included in our

working schedule. Close contact with customers and Knowledge flow in company has caused to

achieve different standards.

Alborz Petrochemical Company operates as a private company through entrepreneurship and the use

of modern technologies. Our company promotes its production by focusing on productivity tools

including up-to-date machinery, professional human resources and proper supply chain management.